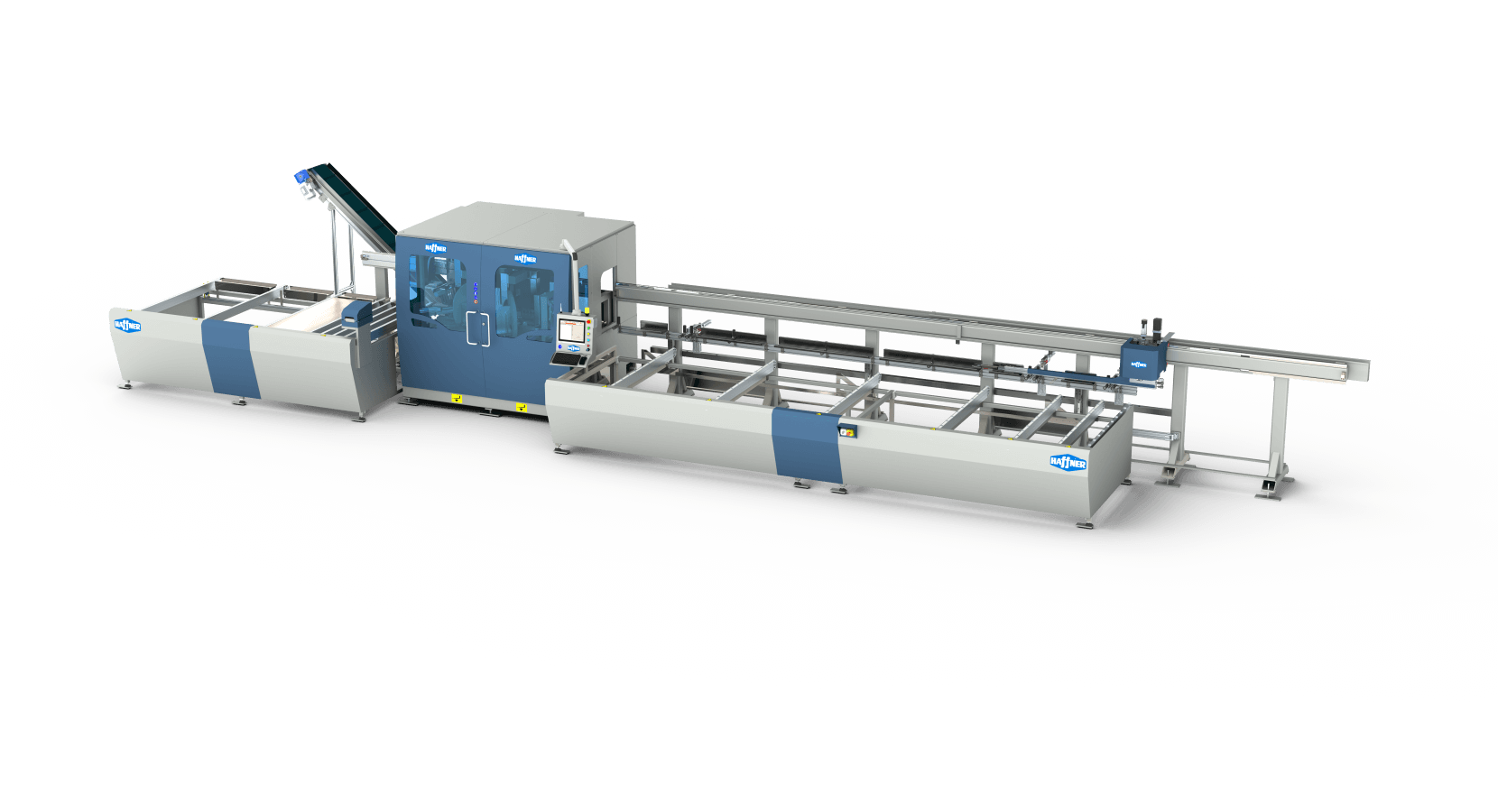

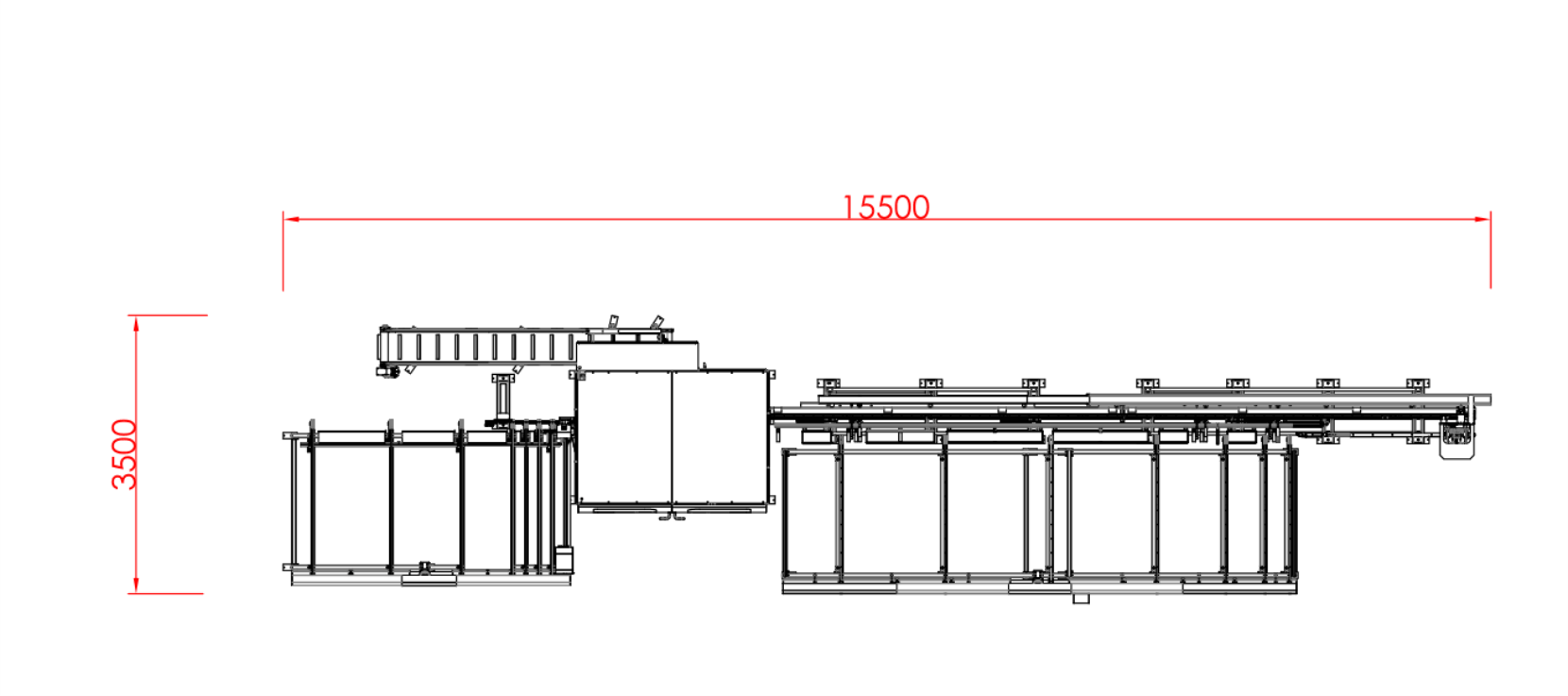

SBA 2PVC Profile Machining Center

SBA 2 Profile Processing Center is designed to perform all cutting, milling, drilling and marking operations on PVC profiles in a single station, as well as special cutting operations such as V-cut, Y-cut and arrowhead cutting on a single computer controlled machine. In this way, the processes performed on 3 different machines (cutting, copy milling, water evacuation) with 3 operators are gathered in a single machine, while the production speed and quality standardization are ensured, labor costs are also remarkably reduced.

The SBA 2 Profile Processing Center allows stacking of 10 profiles up to 6500 mm long on the loading belt. The servo motor controlled profile holder, which can be positioned horizontally automatically, has the ability to hold profiles of different designs and sizes and drive them into the machine. Thanks to the sensor on the profile holder, the lengths of the profiles placed on the loading belt can be measured automatically and taken into production using optimization.

SBA 2 Profile Machining Center is an ergonomic, 15 '' sized, high performance industrial PC with Windows 10 operating system, working without fan between 0 ° C - 55 ° C, developed by Haffner Machinery. It is used with a user-friendly interface. Profiles to be milled and cut can be viewed on the screen in 3D. It can work integrated with door and window software of different brands. Apart from these connections, data can be transferred to the machine via USB port. With both vertical and horizontal pneumatic clamping pistons, the profiles are fixed in the best way and milling and cutting processes are performed with minimum tolerance.

It carries out all operations on the profiles with maximum precision with 12 standard tools on the milling group. In addition to routing discharge slots, it is aimed to increase the production capacity by simultaneously processing the mirror, cylinder and arm parts, which take time to open especially in the door profiles. Thanks to the milling group that can move on 7 axes, it is possible to open discharge slots, perform drilling and milling operations on the profile in maximum flexibility with special router bits. Thanks to servo motors, 3 horizontal saws with a diameter of 550 mm with 0.1 mm precision can automatically make all standard and special cuts. Axes controlled by servo motors work at high speed and precision, ensuring a superior cutting result.

Cutted profile parts are automatically carried on the conveyor belt system and carried right in front of the operator in order to place the reinforcement profile and labels. Labels with barcodes are manually pasted on the profiles by the operator. Production integration is achieved thanks to the readability of the barcodes by CNC Welding and Corner Cleaning machines.

Waste parts are transported to the waste chamber by the automatic conveyor system.

Service support with remote connection, problem detection and solution by connecting to the entire automation system is possible.

The operating system automatically cleans the unnecessary data of the last session at every startup and shutdown of the machine, ensuring maximum security measures against virus and user errors. Daily backup is done automatically to the internal backup unit. The system provides the opportunity to control the production daily, weekly, monthly and yearly with the shift control system. There is a central lubrication system that facilitates machine maintenance.