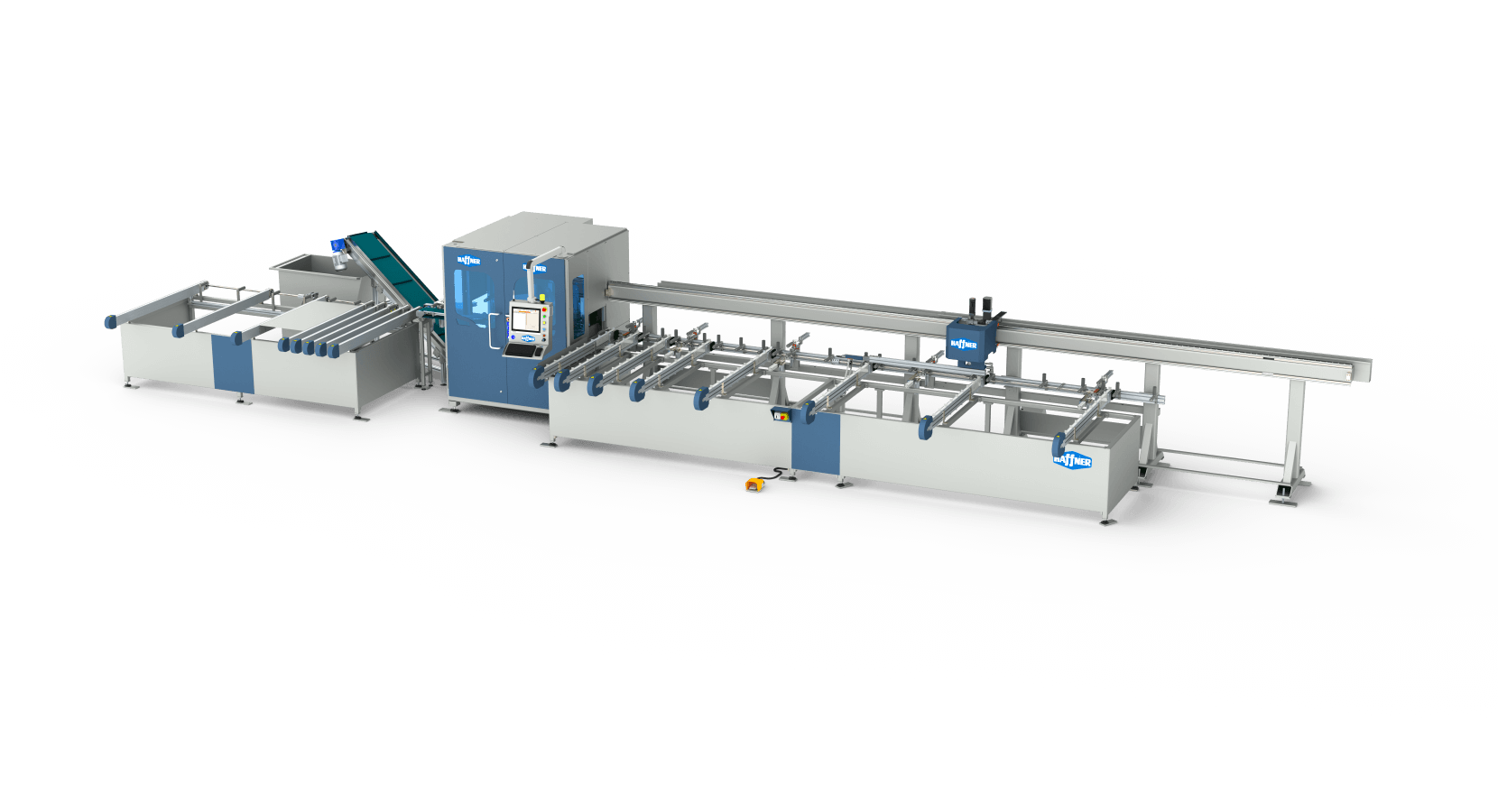

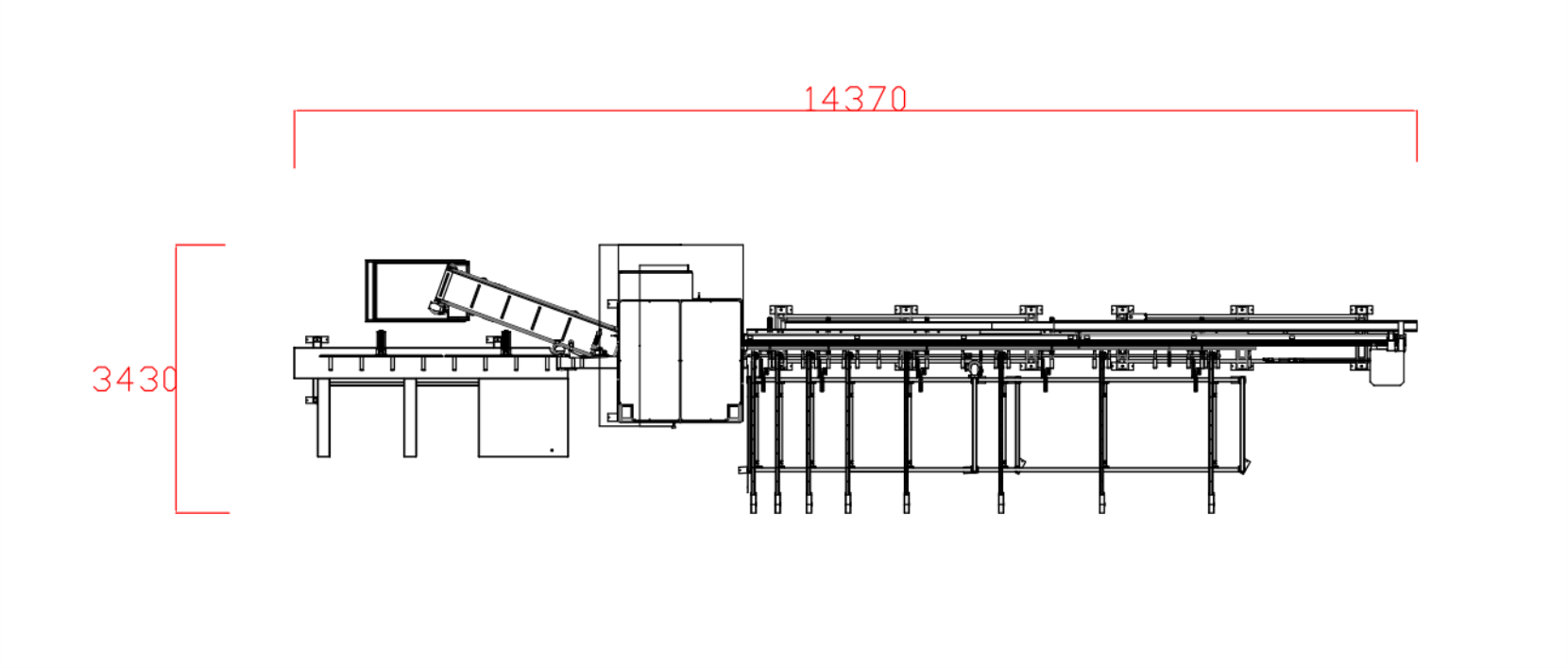

SC 215PVC Profile Machining Center

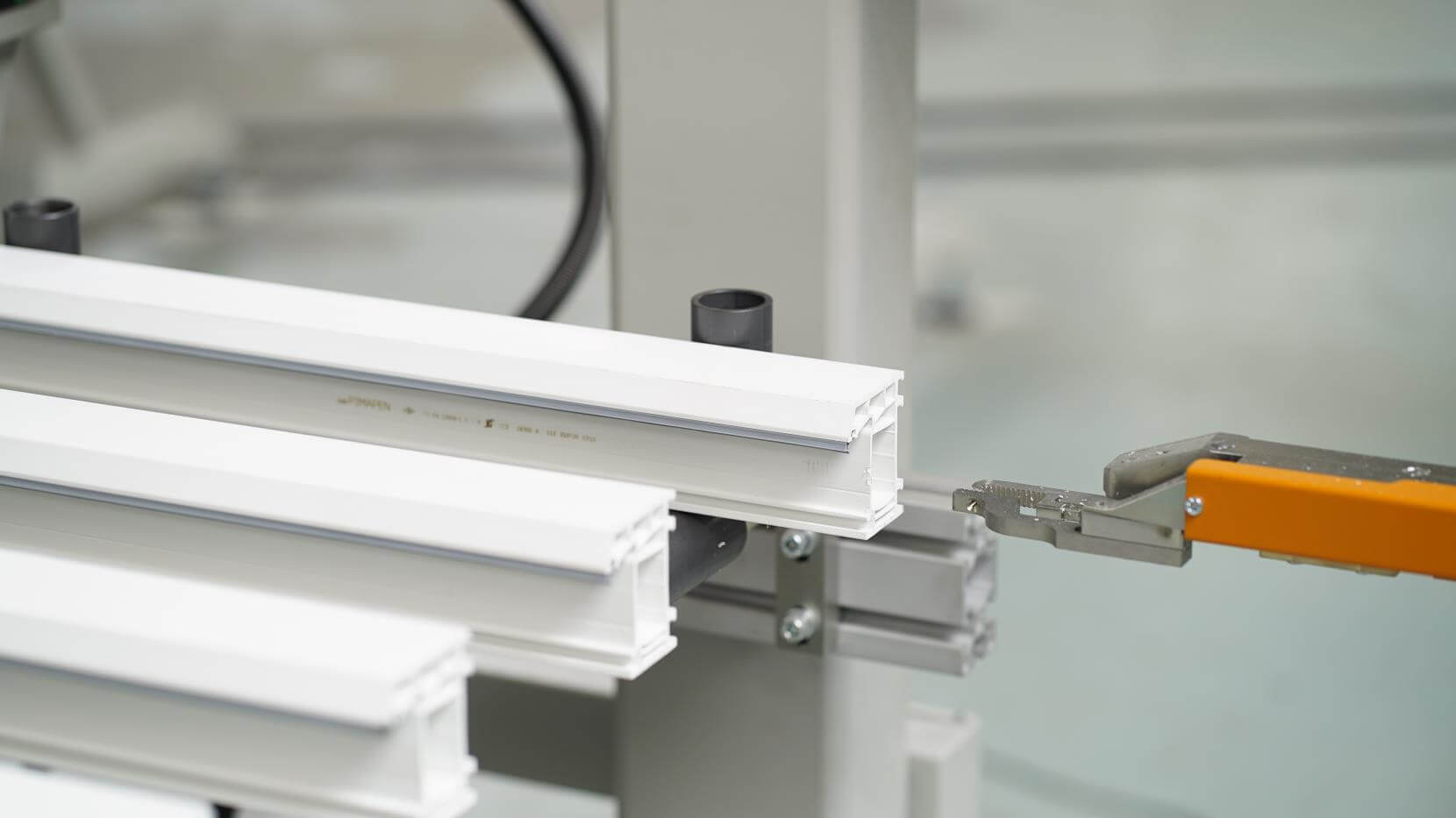

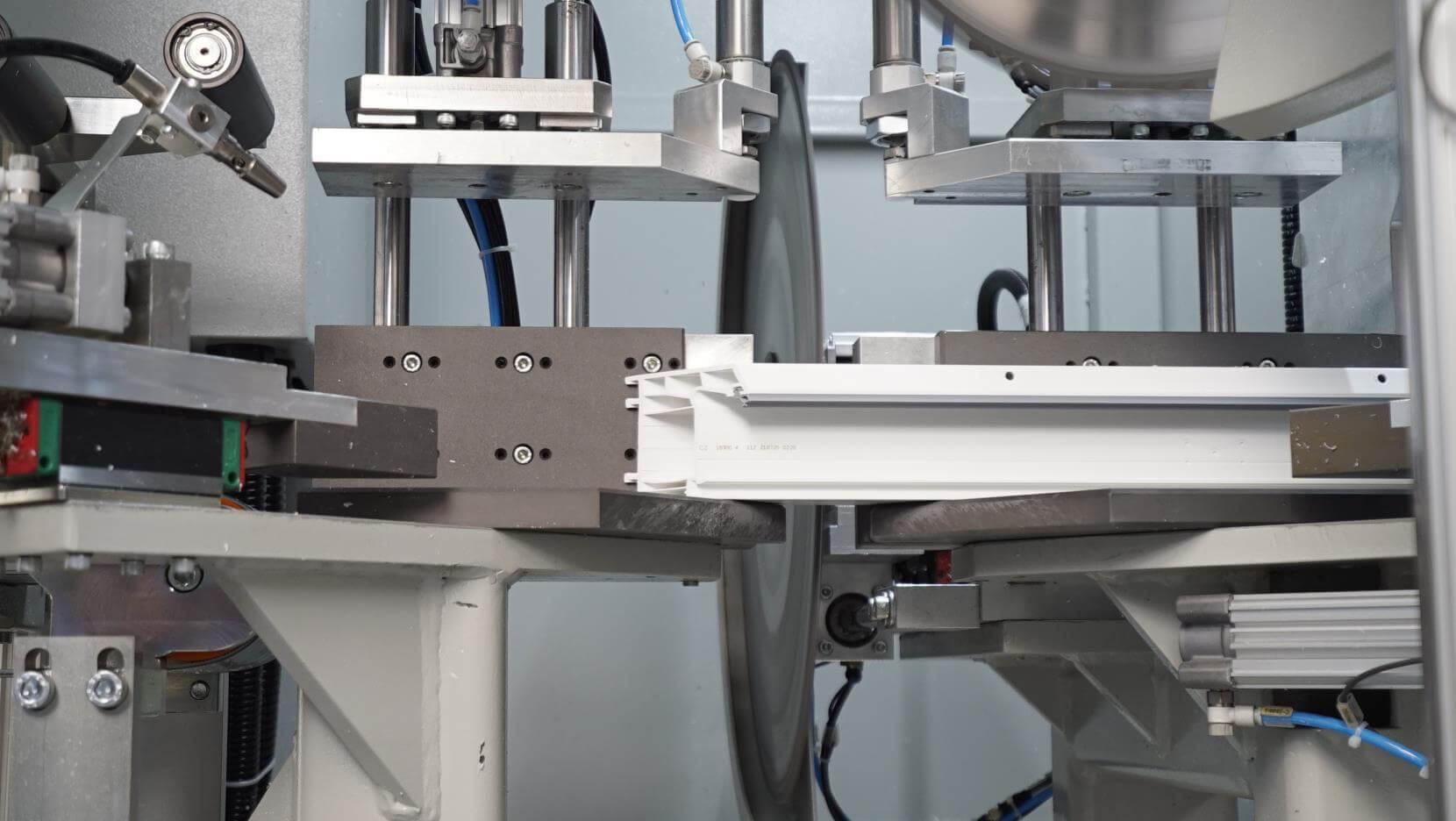

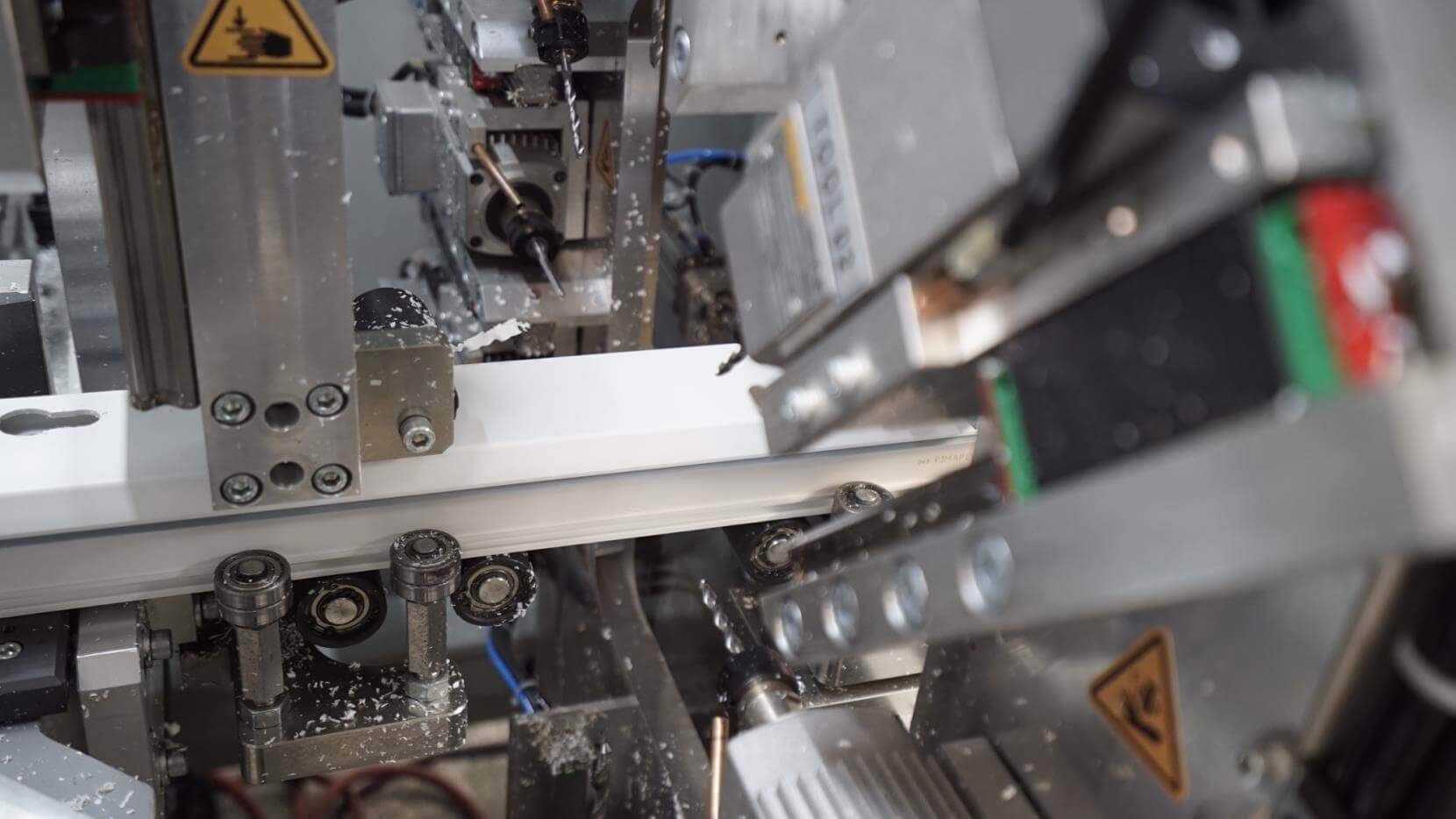

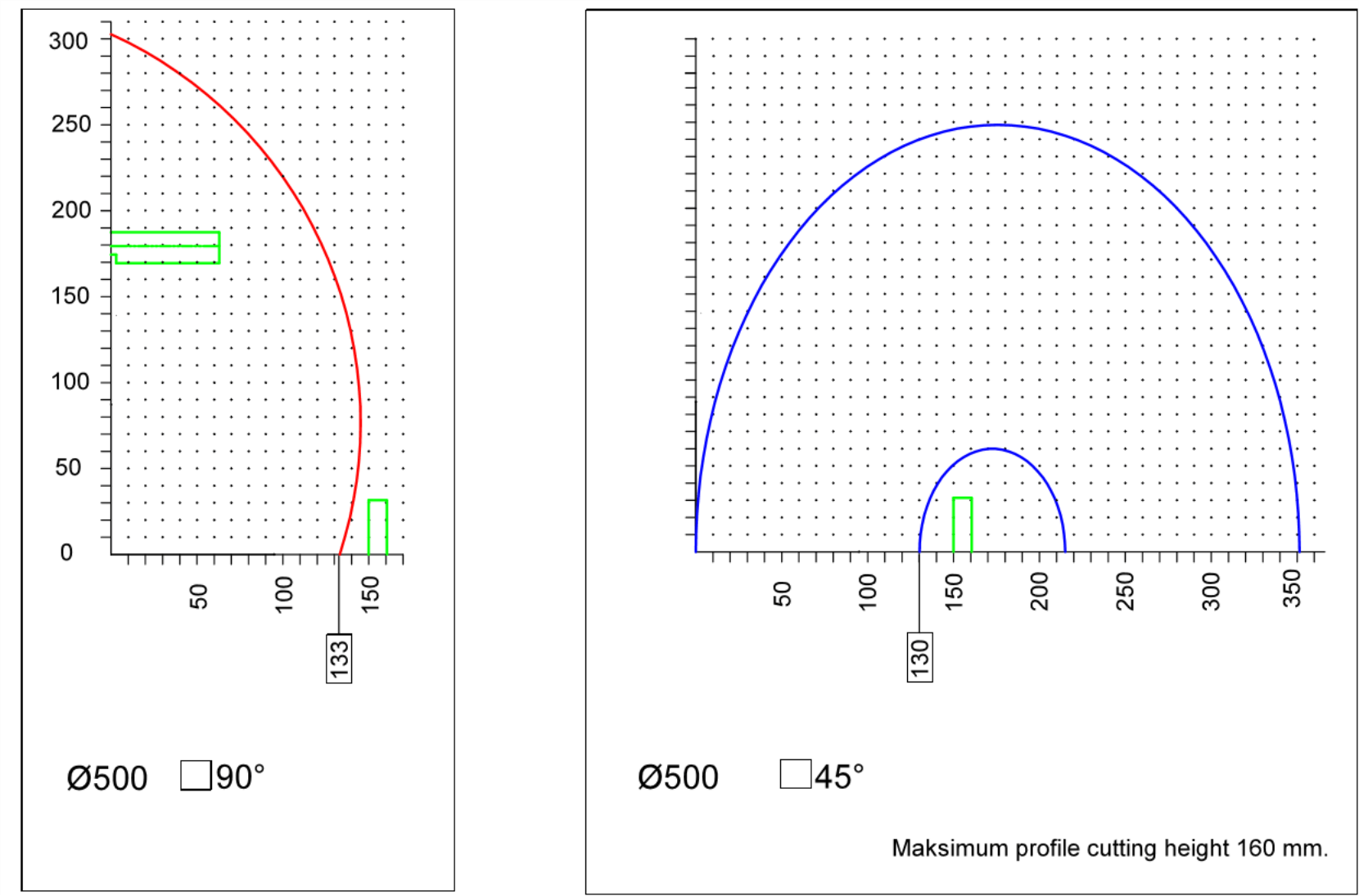

All cutting, milling, drilling and marking processes on PVC profiles are gathered in a single machine with computer control. Capacity to stack 10 profiles. (Maximum length of 6.5 m) It has automatic cutting feature at 45 °, 90 ° and 135 ° angles. System works with high speed and precision thanks to 5 axes controlled by servo motors. It performs angled water drainage channel opening, drilling and milling operations. The remaining waste parts are transported to the waste container by the automatic conveyor system.

It carries out all operations precisely with 8 tools in the milling group.

Manual barcode labeling system is integrated with CNC Welding and Corner Cleaning Production Sets. High performance 22” screen industrial PC with Windows 10 operating system works without a need of a fan between 0 ° C - 55 ° C.

System works with the production data coming from different window production software with minimum wastage. With the interface program developed by the Haffner Machinery Software Department, all error messages can be displayed on the screen. It is suitable for problem detection and solution by remote connection It offers the feature of wireless network connection or data transfer from USB. It provides the ability to automatically perform daily backup to the internal backup unit. With the shift control system, it provides the opportunity to control the production on a daily, weekly, monthly and yearly basis. There is a central lubrication system that facilitates machine maintenance.